Additive Manufacturing

An extensive range of technologies and materials for AM under one roof with a world class manufacturing facility

Additive Manufacturing

An extensive range of technologies and materials for AM under one roof with a world class manufacturing facility

About Us

Established in 2019 as a subsidiary of its own parent company SUNFAB. PRIMAEAM Solutions Private Limited is an additive parts manufacturing service bureau company in Chennai, India. Having an extensive range of 3D printing materials in Metal and Thermoplastics, We Offer products and services to Aerospace, Automotive, Consumer Electronics & Goods, Healthcare, Industrial Engineering, Process Industries and Transportation.

We assist you in adopting additive manufacturing (3D printing). Our dedicated additive manufacturing facility and process ensure to provide the aesthetics and functionalities of your product, as close as possible to your idea. We offer wide range of services including Design for Additive Manufacturing (DFAM), Topology Optimization, Data Optimization for Prototyping, Representation models (look and feel), Functional prototype, Miniatures, Batch production and low volume production

Our Services

Design for additive manufacturing (DFAM)

Design of implants, prosthetic & Engineering parts through our customer experience, innovation & incubation centre.

Topology Optimization

Optimized design & material layout for your parts.

Material Selection

Selecting suitable material based on the application.

Process Selection

Evaluate the manufacturability

(EBM, SLM, FDM, SLA, MJF, FFF).

Post Processing

End use parts with required surface finish and dimensional accuracy.

Manufacturing (3D Printing)

Data Optimization

File preparation (STL), complex cuts, generation of reinforcement structures.

Send STL File

Consultation

Review Quotation

Printing

Technology

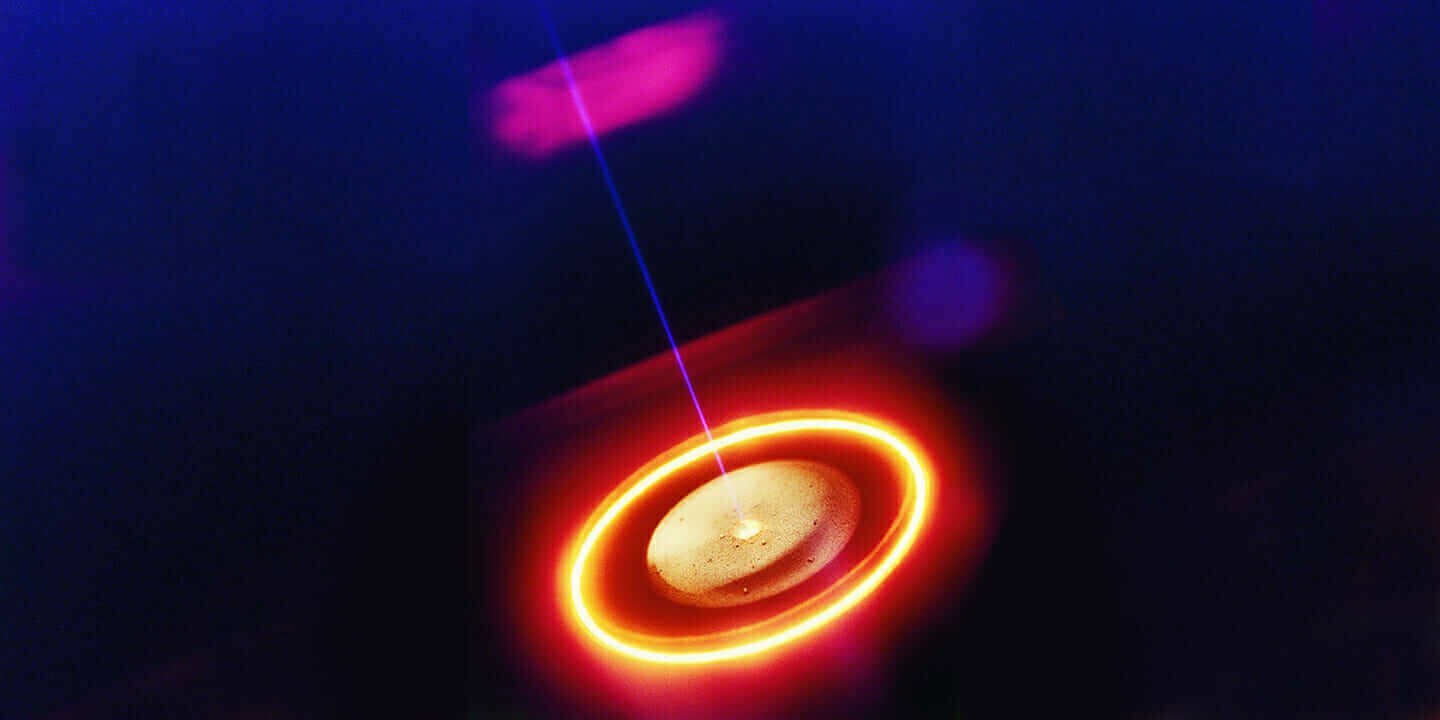

ARCAM EBM Q10 PLUS

First of its kind in South India with 3 kW Electron Beam Source.

Build Volume: 200 mm x 200 mm x 180 mm

Applications

- Cranio-Maxillofacial Implants

- Standard Orthopedic Implants

- Patient-Specific Implants

EBM uses a high energy electron beam to induce fusion between the particles of a metal powder. A focused electron beam scans across a thin layer of powder causing localized melting and solidification over a specific cross-sectional area. Electron beam systems produce minimal residual stresses in parts, resulting in less distortion and less need for anchors and support structures. Moreover, EBM uses less energy and can produce layers at a faster rate than SLM and DMLS, but the minimum feature size, powder particle size, layer thickness and surface finish are typically of lower quality. EBM also requires the parts to be produced in vacuum and the process can only be used with conductive materials.

SLM 280 V2.0

First of its kind in India with a 700 W twin laser technology.

Build Volume: 280 mm x 280 mm x 365 mm

Applications

- Surgical Guides and Tools

- Tools, Jigs and Fixtures

- Aerospace Functional Components

- Automotive Functional Components

Selective Laser Melting (SLM) or Laser Powder Bed Fusion (LPBF) uses a high-power laser source to melt and fuse metallic powders together. A focused laser beam source selectively melts metallic powders along a thin layer, depending upon the cross-section of the part. The process repeats layer-by-layer until the final part is built. Laser based powder bed fusion technology supports a wide variety of materials to be 3D printed and can produce better surface finish with minimum feature size.

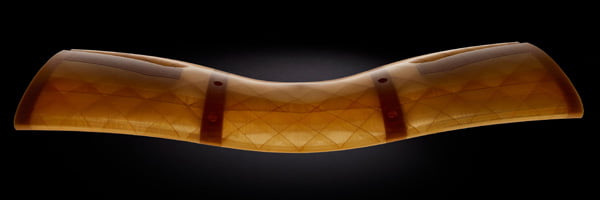

STRATASYS FORTUS 450MC

Ideal for printing high-performance thermoplastics

Build Volume: 405 mm x 355 mm x 406 mm

Applications

- Medical Devices, Surgical Guides

- Functional Prototypes

- Aerospace Interiors

- Aerospace MRO products

- Tools, Jigs and Fixtures

Fused Deposition Modeling (FDM) is an additive manufacturing process that belongs to the material extrusion family. In FDM, an object is built by selectively depositing melted material in a pre-determined path layer-by-layer. The materials used are high-performance thermoplastic polymers that come in a filament form.

MARKFORGED X7

Ideal for printing continuous fiber reinforced parts that deliver superior strength, accuracy, and surface finish.

Build Volume: 330 mm x 270 mm x 200 mm

Applications

- Tools, Jigs and Fixtures

- UAV Applications

- Space exploration and Aerospace components

Fused Filament Fabrication (FFF) is an additive manufacturing process that uses a continuous filament of a thermoplastic or composite matrix and fiber materials. In FFF, filaments of material are heated and then fed from a large spool through a printing nozzle, which is then deposited layer-by-layer to build the part. The materials used here are composites with continuous fiber reinforcements, which offer lightweight solutions at superior strength.

HP MULTI-JET FUSION 5200 SERIES

India’s first production series Multi-Jet Fusion with midvolume production capability.

Build Volume: 380 mm x 284 mm x 380 mm

Applications

- Prosthetics and Orthotics

- Functional Prototypes

- Aerospace products

- Automotive products

Multi Jet Fusion (MJF) is essentially a combination of the SLS and Material Jetting technologies. A carriage with inkjet nozzles (similar to the nozzles used in desktop 2D printers) passes over the print area, depositing fusing agent on a thin layer of plastic powder. At the same time, a detailing agent that inhibits sintering is printed near the edge of the part. A high energy IR source then passes over the build bed and sinters the areas where the fusing agent was dispensed, while leaving the rest of the powder untouched. The process repeats until all parts are complete.

FORMLABS FORM 3L

Compact 3D printer to print parts with smooth surface finish and fine detail.

Build Volume: 335 mm x 200 mm x 300 mm

Applications

- Functional prototypes

- High resolution prototypes and models

- Jigs and Fixtures for manufacturing

- Form and Fit testing products

Stereolithography (SLA) is an additive manufacturing technology in which a liquid photosensitive resin is converted into a solid by exposing it to an UV source. The photopolymers are solidified by the source and forms a single layer of the desired part. The process is repeated layer-by-layer until the final part is printed.

Materials

ABS M30i (Acrylonitrile Butadiene Styrene) is a biocompatible thermoplastic with high strength and toughness. It is well suited for medical, pharmaceutical and food packaging applications.

ABS M30 (Acrylonitrile Butadiene Styrene) is a high-performance thermoplastic characterized by high strength and toughness, while being lightweight and resilient. It is best suited for production materials, accurate prototyping, and general use cases.

ABS ESD 7 (Acrylonitrile Butadiene Styrene) is an ABS high-performance thermoplastic with static dissipative properties suited for discharge sensitive applications such as electronic assemblies, jigs and fixtures, functional prototyping.

Antero 800NA (Polyetherketoneketone) is a high-performance thermoplastic which exhibits high wear resistance, heat resistance and chemical resistance properties. It is best suited for aerospace components that demand low outgassing and dimensional stability and chemical resistant industrial parts.

ASA (Acrylonitrile Styrene Acrylate) is an ABS-like material possessing better UV resistance, aesthetics and mechanical properties than ABS. It is well suited for production parts for outdoor functional prototyping, automotive parts, and accessory types.

PC (Polycarbonate) is a thermoplastic material characterized by its high strength, high impact resistance and heat resistance properties. It is well suited for accurate, durable, stable long parts, patterns for metal bending, industrial prototyping needs, tools, and fixtures.

Nylon 12 (Polyamide 12) has good strength properties, resistance to moderate chemicals and high fatigue resistance. These characteristics make it a good choice for applications involving snap-fit closures, tools with press-fit inserts, components subject to high vibration and parts requiring threaded inserts.

Nylon 12CF (Polyamide reinforced with chopped carbon fiber) has a carbon filled thermoplastic with excellent structural characteristics with highest flexural strength and stiffness to weight ratio.

ULTEM 1010 (Polyetherimide) is a high-performance thermoplastic with excellent heat resistance, chemical resistance, flame retardant, and tensile properties. It is ideal for food production tools, aerospace interiors, MRO, and automotive components.

ULTEM 9085 (Polyetherimide) is a flame-retardant high-performance thermoplastic with high strength-to-weight ratio and high FST (flame, toxicity, and smoke) rating. It is an excellent choice for commercial transportation industry – specifically aerospace, ground and marine vehicles.

PA 11 (Polyamide 11) is a thermoplastic material delivering optimal mechanical properties. Provides excellent chemical resistance and enhanced elongation-at-break, Impact resistance and ductility for prostheses, insoles, sports goods, snap fits, living hinges, and more.

PA 12 (Polyamide 12) is a robust thermoplastic material which produces high-density parts with balanced property profiles and strong structures. It provides excellent chemical resistance to oils, greases, aliphatic hydrocarbons, and alkalies. Ideal for complex assemblies, housings, enclosures, and watertight applications. Biocompatibility certifications—meets USP Class I-VI and US FDA guidance for Intact Skin Surface Devices.

PA 12GB (Polyamide 12 Glass Bead) is a 40% glass bead filled thermoplastic material with both optimal mechanical properties and high reusability. Provides dimensional stability along with repeatability. Ideal for applications requiring high stiffness like enclosures and housings, fixtures, and tooling.

Standard Resins (Clear, White, Grey, Black, Color Base)

Standard Resins are liquid photopolymers with high Resolution, Strength, Precision and Surface finish purposes – Ideal for rapid prototyping and product development, for capturing finest details in the model. Their features vary from polished to transparent to opaque and matt finish.

Draft Resin is a liquid photopolymer that prints up to four times faster than Formlabs standard materials, making it ideal for initial prototypes and rapid iterations to help bring products to market faster. Parts printed with Draft Resin exhibit a smooth grey finish and high accuracy.

Tough 1500 Resin is the most resilient material in the family of Tough and Durable Resins. Ideal for prototypes that repeatedly bend and quickly return to shape, Jigs and fixtures requiring repeated deflection, thus simulating the strength and stiffness of polypropylene (PP).

Tough 2000 Resin is the strongest and stiffest material in the functional family of Tough and Durable Resins. Ideal for – Strong and stiff prototypes, Jigs and fixtures requiring minimal deflection, thus simulating the strength and stiffness of ABS.

Durable Resin is impact resistant and highly wear resistant, capable of extreme deformation before breaking, and has low friction compared to standard resins and Tough 2000 Resin. Ideal for

- Parts requiring high impact strength

- Parts requiring high impact strength

- Parts that require a low-friction surface, like ball joints

- Parts that are both rigid and flexible, Snap-fit parts and flexures

Rigid Resins can be used for prototyping strong and stiff parts that need to resist bending. Parts made from these materials are thermally and chemically resistant and will be dimensionally stable under load but will experience brittle failure if pushed to their limits.

- Jigs, fixtures, and tooling

- Turbines and fan blades

- Fluid and airflow components

- Electrical casings and automotive housings

Grey Pro Resin is an Engineering Resin designed for high precision, moderate elongation, and low creep. These mechanical properties make Grey Pro Resin a versatile material for a wide range of engineering applications, including concept modelling and functional prototyping. Highly resistant to deformation over time, Grey Pro Resin is especially suitable for printing parts intended for repeated use or handling.

Formlabs High Temp Resin has a heat deflection temperature (HDT) of 238 °C @ 0.45 MPa—the highest among Formlabs resins.

Ideal for:

- Mold prototyping

- Heat-resistant fixtures

- Low pressure fluidics

- Environmental testing

A cost-effective solution for producing static-dissipative parts designed to endure use on the factory floor, use ESD Resin to reduce risk and increase the yield on your manufacturing line by 3D printing custom tools, jigs, and fixtures for automotive, aerospace, electronics manufacturing. Ideal for:

- Anti-static prototypes and end-use parts

- Housings for sensitive electronics

- Tooling, jigs, and fixtures for electronics manufacturing

Flexible 80A Resin is the stiffest soft-touch material in our library of Flexible and Elastic Resins, with an 80A Shore durometer to simulate the flexibility of rubber or TPU. Balancing softness with strength, Flexible 80A Resin can withstand bending, flexing, and compression, even though repeated cycles. Ideal for:

- Handles

- grips and overmolds

- Cushioning and damping

- Wearables prototyping

Elastic 50A Resin is an elastomeric material designed for applications requiring high elongation and high energy return. Use Elastic 50A Resin for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing. Elastic is transparent, which makes it well suited for medical models for simulation or education. Ideal for:

- Compliant features for robotics

- Medical models and devices

- Wearables and consumer goods prototyping

A 20% wax-filled material, Castable Wax Resin prints both delicate and bulky models with ease. It captures intricate features and offers smooth surface finish for accurate castings with zero ash content and clean burnout. Printed parts are strong enough to handle with no post-cure required, allowing for a fast and simple workflow. Ideal for:

A fast-printing material for production of high-accuracy restorative models. Dental Model Resin meet the precision, reliability, and throughput requirements of restorative dentistry. Print accurate models and dies with crisp margins and contacts, delivering high-quality results on fast-paced timelines.

Ideal for:

Titanium Alloy (Medical Grade)

The high strength, low weight ratio and outstanding corrosion resistance inherent to titanium and its alloys has led to a wide and diversified range of successful applications which demand high levels of reliable performance in surgery and medicine as well as in aerospace, automotive, chemical plant, power generation, oil and gas extraction, sports, and other major industries. Ti6Al4V ELI (Grade 23) is biocompatible, ideal for direct contact with tissue and bone.

AlSi10Mg is a hardenable aluminium-based alloy with a combination of achievable high strengths while maintaining dynamic load capacity. It is highly suitable for processing and characterized by a good resistance in corrosive atmospheres as well as high electrical conductivity. It has a wide variety of applications ranging from thin-walled components to parts with complex geometries, ideal for use in the aerospace and automotive industries.

3D printed stainless steel can offer exceptional hardness, high ductility, and outstanding corrosion-resistant properties. The good mechanical characteristic values of stainless steel make it suitable for use in places that are exposed to heavy strain due to its high wear resistant properties.

The following stainless-steel grades are available for manufacturing products at PRIMAEAM –

Stainless steel 316L

Biocompatible steel with applications in medical technologies, automotive, and aerospace engineering

Stainless steel 17-4PH

Martensitic Precipitation-Hardenable Cr-Ni-Cu steel – Widely used in aerospace, chemical, petrochemical, and general metal working industries.

Stainless steel 15-5PH

Stainless, Martensitic, and Hardenable Cr-Ni-Cu Steel with good weldability and forgeability – Widely used in the medical, aerospace and automotive areas.

Components made of tool steel possess exceptional hardness, great corrosion-resistance, and outstanding wear-resistance properties. Their specific mechanical properties extend their usage in high-stressed components and high temperature applications. An SLM®-specific benefit is the layer-wise manufacturing, which allows to implement cooling channels into the component.

The following stainless-steel grades are available for manufacturing products at PRIMAEAM –

Tool Steel 1.2709

High ductility, exceptional hardness, high creep-resistant and wear-resistant alloy – Primarily used for manufacturing tools and molds.

Tool Steel 1.2344

High ductility and exceptional hardness – widely used in heavy strain applications and producing tools and molds.

Inconel is a nickel-chromium based alloy, which is the primary material of choice for aircraft engine components with service temperatures below 700°C. The alloy has a combination of exceptional corrosion resistance at temperatures upto 1000°C with outstanding weldability and resistance to post-weld cracking. Due to its excellent creep-resistant properties, the alloy can withstand ruptures due to creep upto 700°C.

The following stainless-steel grades are available for manufacturing products at PRIMAEAM –

IN625

IN625 is a precipitation-hardenable nickel-chromium alloy containing also significant amounts of iron, niobium, and molybdenum along with lesser amounts of aluminum and titanium. It is widely used in aircraft engine components with service temperatures upto 650°C.

IN718

IN718 is a Precipitation-Hardenable Nickel-Chromium alloy with a density of about 8.2 g/cm3. It is widely used in components for gas turbines, rocket parts, and general high temperature environments. The alloy has exceptional, tensile, fatigue, creep and rupture strength at temperatures upto 700°C.

Onyx™ is a micro carbon fiber filled nylon that yields accurate parts with near flawless surface finish. It offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts.

- Plastic Part Replacement

- Housings

- Sensor Mounts

- Cosmetic Prototypes

Onyx™ FR is a flame-retardant variant of Onyx™ designed for use in applications where parts must be non-flammable. The material earned a UL 94 Blue Card and is considered V-0 (self-extinguishing) at thicknesses greater than or equal to 3mm. It can be reinforced with any Continuous Fiber and is compatible with industrial composite 3D printers.

- Weld Fixturing

- Aerospace Clips & Brackets

- Laser Marking Fixtures

- Energy/Electrical Brackets & Fixtures

Onyx™ ESD is a static-dissipative chopped carbon-fibre nylon material, precision-engineered for a tight range of surface resistance. Onyx ESD meets ESD-safe requirements of the most stringent manufacturers, while offering the same industry-leading print quality of Onyx. It is stronger and stiffer than Onyx, with the same near perfect surface finish, making it suitable for advanced manufacturing applications from electronics assembly to industrial robotics and process automation.

- Vacuum Grippers

- Transfer Tools

- Pick and Place

- Transfer and Packaging Trays

- Electronics Enclosures

Precise PLA is our easy-to-print plastic for precision concept modeling and validation. Based on the most common 3D printing prototyping material, Precise PLA 3D prints without warping and comes in a variety of colors. With high design freedom and affordability, you can fine tune your designs before implementation.

- Part prototypes

- Fit checks

- Color coded indicators

Nylon is an unfilled thermoplastic. It’s a non-abrasive material that is great for ergonomic surfaces and work holding for pieces that are easily marred. It can be painted or dyed.

- Ergonomic Tools

- Assembly Trays

- Cosmetic Parts

Carbon Fiber is an ultra-high-strength Continuous Fiber — when laid into a Composite Base material like Onyx, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff, strong, and can be automatically laid down in a wide variety of geometries.

- High-Strength Tools & Fixtures

- Brackets & Mounts

- Inspection/CMM Fixturing

- Bespoke End-Use Parts

- Functional Prototypes

Carbon Fiber FR is a flame-retardant variant of ultra-high-strength Continuous Carbon Fiber — when used to reinforce a Composite Base material like Onyx FR, it can yield parts as strong as 6061-T6 Aluminum. Onyx FR-A and Carbon Fiber FR-A are purpose-built for the requirements of the aerospace, transportation, and automotive industries. FR-A materials establish lot-level material traceability and pass the test suite necessary for qualification under 14 CFR 25.853 for most 3D-printable parts.

- Aerospace Cabin Components

- Brackets & Mounts

- Aerospace MRO & Spare Parts

- End-Use Parts

- Functional Prototypes

Aramid Fiber is a Kevlar® based, specialized Continuous Fiber known for its energy absorption and extreme toughness. When laid into Onyx or another Composite Base material, it yields impact-resistant parts that are nearly immune to catastrophic failure (fracture). It’s perfect for use in parts that are in demanding environments or are subject to repetitive loading.

- End-of-Arm Tooling

- Stanchions, Cradles, & Supports

- Delrin® Part Replacements

- Wear Stops

High Strength High Temperature (HSHT) Fiberglass is defined by two characteristics: high strength (nearly equal to 6061-T6 Aluminum) and strength in high temperatures. Though not as stiff as Continuous Carbon Fiber, Onyx parts reinforced with HSHT are strong at both low and high temperatures. As a result, HSHT reinforcement is best used for parts in high-temperature environments like molds, autoclaves, and others.

- Polymer Molds

- Prototype (Low-Run) Injection Molds

- High-Temperature Fixturing

- High-Temperature Prototypes

Fiberglass is an entry-level Continuous Fiber —a material capable of yielding parts 10x stronger than ABS when laid into a Composite Base material like Onyx.

- Soft jaws

- Medium-Strength Tooling

- Insulative Reinforcement

- Hand Tools

Thermoplastics

ABS M30i (Acrylonitrile Butadiene Styrene) is a biocompatible thermoplastic with high strength and toughness. It is well suited for medical, pharmaceutical and food packaging applications.

ABS M30 (Acrylonitrile Butadiene Styrene) is a high-performance thermoplastic characterized by high strength and toughness, while being lightweight and resilient. It is best suited for production materials, accurate prototyping, and general use cases.

ABS ESD 7 (Acrylonitrile Butadiene Styrene) is an ABS high-performance thermoplastic with static dissipative properties suited for discharge sensitive applications such as electronic assemblies, jigs and fixtures, functional prototyping.

Antero 800NA (Polyetherketoneketone) is a high-performance thermoplastic which exhibits high wear resistance, heat resistance and chemical resistance properties. It is best suited for aerospace components that demand low outgassing and dimensional stability and chemical resistant industrial parts.

ASA (Acrylonitrile Styrene Acrylate) is an ABS-like material possessing better UV resistance, aesthetics and mechanical properties than ABS. It is well suited for production parts for outdoor functional prototyping, automotive parts, and accessory types.

PC (Polycarbonate) is a thermoplastic material characterized by its high strength, high impact resistance and heat resistance properties. It is well suited for accurate, durable, stable long parts, patterns for metal bending, industrial prototyping needs, tools, and fixtures.

PC (Polycarbonate) is a thermoplastic material characterized by its high strength, high impact resistance and heat resistance properties. It is well suited for accurate, durable, stable long parts, patterns for metal bending, industrial prototyping needs, tools, and fixtures.

Nylon 12CF (Polyamide reinforced with chopped carbon fiber) has a carbon filled thermoplastic with excellent structural characteristics with highest flexural strength and stiffness to weight ratio.

ULTEM 1010 (Polyetherimide) is a high-performance thermoplastic with excellent heat resistance, chemical resistance, flame retardant, and tensile properties. It is ideal for food production tools, aerospace interiors, MRO, and automotive components.

ULTEM 9085 (Polyetherimide) is a flame-retardant high-performance thermoplastic with high strength-to-weight ratio and high FST (flame, toxicity, and smoke) rating. It is an excellent choice for commercial transportation industry – specifically aerospace, ground and marine vehicles.

PA 11 (Polyamide 11) is a thermoplastic material delivering optimal mechanical properties. Provides excellent chemical resistance and enhanced elongation-at-break, Impact resistance and ductility for prostheses, insoles, sports goods, snap fits, living hinges, and more.

PA 12 (Polyamide 12) is a robust thermoplastic material which produces high-density parts with balanced property profiles and strong structures. It provides excellent chemical resistance to oils, greases, aliphatic hydrocarbons, and alkalies. Ideal for complex assemblies, housings, enclosures, and watertight applications. Biocompatibility certifications—meets USP Class I-VI and US FDA guidance for Intact Skin Surface Devices.

PA 12GB (Polyamide 12 Glass Bead) is a 40% glass bead filled thermoplastic material with both optimal mechanical properties and high reusability. Provides dimensional stability along with repeatability. Ideal for applications requiring high stiffness like enclosures and housings, fixtures, and tooling.

Thermoset Resins

Standard Resins (Clear, White, Grey, Black, Color Base)

Standard Resins are liquid photopolymers with high Resolution, Strength, Precision and Surface finish purposes – Ideal for rapid prototyping and product development, for capturing finest details in the model. Their features vary from polished to transparent to opaque and matt finish.

Draft Resin is a liquid photopolymer that prints up to four times faster than Formlabs standard materials, making it ideal for initial prototypes and rapid iterations to help bring products to market faster. Parts printed with Draft Resin exhibit a smooth grey finish and high accuracy.

Tough 1500 Resin is the most resilient material in the family of Tough and Durable Resins. Ideal for prototypes that repeatedly bend and quickly return to shape, Jigs and fixtures requiring repeated deflection, thus simulating the strength and stiffness of polypropylene (PP).

Tough 2000 Resin is the strongest and stiffest material in the functional family of Tough and Durable Resins. Ideal for – Strong and stiff prototypes, Jigs and fixtures requiring minimal deflection, thus simulating the strength and stiffness of ABS.

Durable Resin is impact resistant and highly wear resistant, capable of extreme deformation before breaking, and has low friction compared to standard resins and Tough 2000 Resin. Ideal for

- Parts requiring high impact strength

- Parts requiring high impact strength

- Parts that require a low-friction surface, like ball joints

- Parts that are both rigid and flexible, Snap-fit parts and flexures

Rigid Resins can be used for prototyping strong and stiff parts that need to resist bending. Parts made from these materials are thermally and chemically resistant and will be dimensionally stable under load but will experience brittle failure if pushed to their limits.

- Jigs, fixtures, and tooling

- Turbines and fan blades

- Fluid and airflow components

- Electrical casings and automotive housings

Grey Pro Resin is an Engineering Resin designed for high precision, moderate elongation, and low creep. These mechanical properties make Grey Pro Resin a versatile material for a wide range of engineering applications, including concept modelling and functional prototyping. Highly resistant to deformation over time, Grey Pro Resin is especially suitable for printing parts intended for repeated use or handling.

Formlabs High Temp Resin has a heat deflection temperature (HDT) of 238 °C @ 0.45 MPa—the highest among Formlabs resins.

Ideal for:

- Mold prototyping

- Heat-resistant fixtures

- Low pressure fluidics

- Environmental testing

A cost-effective solution for producing static-dissipative parts designed to endure use on the factory floor, use ESD Resin to reduce risk and increase the yield on your manufacturing line by 3D printing custom tools, jigs, and fixtures for automotive, aerospace, electronics manufacturing. Ideal for:

- Anti-static prototypes and end-use parts

- Housings for sensitive electronics

- Tooling, jigs, and fixtures for electronics manufacturing

Flexible 80A Resin is the stiffest soft-touch material in our library of Flexible and Elastic Resins, with an 80A Shore durometer to simulate the flexibility of rubber or TPU. Balancing softness with strength, Flexible 80A Resin can withstand bending, flexing, and compression, even though repeated cycles. Ideal for:

- Handles

- grips and overmolds

- Cushioning and damping

- Wearables prototyping

Elastic 50A Resin is an elastomeric material designed for applications requiring high elongation and high energy return. Use Elastic 50A Resin for parts that will bend, stretch, compress, and hold up to repeated cycles without tearing. Elastic is transparent, which makes it well suited for medical models for simulation or education. Ideal for:

- Compliant features for robotics

- Medical models and devices

- Wearables and consumer goods prototyping

A 20% wax-filled material, Castable Wax Resin prints both delicate and bulky models with ease. It captures intricate features and offers smooth surface finish for accurate castings with zero ash content and clean burnout. Printed parts are strong enough to handle with no post-cure required, allowing for a fast and simple workflow. Ideal for:

A fast-printing material for production of high-accuracy restorative models. Dental Model Resin meet the precision, reliability, and throughput requirements of restorative dentistry. Print accurate models and dies with crisp margins and contacts, delivering high-quality results on fast-paced timelines.

Ideal for:

Metals

Titanium Alloy (Medical Grade)

The high strength, low weight ratio and outstanding corrosion resistance inherent to titanium and its alloys has led to a wide and diversified range of successful applications which demand high levels of reliable performance in surgery and medicine as well as in aerospace, automotive, chemical plant, power generation, oil and gas extraction, sports, and other major industries. Ti6Al4V ELI (Grade 23) is biocompatible, ideal for direct contact with tissue and bone.

AlSi10Mg is a hardenable aluminium-based alloy with a combination of achievable high strengths while maintaining dynamic load capacity. It is highly suitable for processing and characterized by a good resistance in corrosive atmospheres as well as high electrical conductivity. It has a wide variety of applications ranging from thin-walled components to parts with complex geometries, ideal for use in the aerospace and automotive industries.

3D printed stainless steel can offer exceptional hardness, high ductility, and outstanding corrosion-resistant properties. The good mechanical characteristic values of stainless steel make it suitable for use in places that are exposed to heavy strain due to its high wear resistant properties.

The following stainless-steel grades are available for manufacturing products at PRIMAEAM –

Stainless steel 316L

Biocompatible steel with applications in medical technologies, automotive, and aerospace engineering

Stainless steel 17-4PH

Martensitic Precipitation-Hardenable Cr-Ni-Cu steel – Widely used in aerospace, chemical, petrochemical, and general metal working industries.

Stainless steel 15-5PH

Stainless, Martensitic, and Hardenable Cr-Ni-Cu Steel with good weldability and forgeability – Widely used in the medical, aerospace and automotive areas.

Components made of tool steel possess exceptional hardness, great corrosion-resistance, and outstanding wear-resistance properties. Their specific mechanical properties extend their usage in high-stressed components and high temperature applications. An SLM®-specific benefit is the layer-wise manufacturing, which allows to implement cooling channels into the component.

The following stainless-steel grades are available for manufacturing products at PRIMAEAM –

Tool Steel 1.2709

High ductility, exceptional hardness, high creep-resistant and wear-resistant alloy – Primarily used for manufacturing tools and molds.

Tool Steel 1.2344

High ductility and exceptional hardness – widely used in heavy strain applications and producing tools and molds.

Inconel is a nickel-chromium based alloy, which is the primary material of choice for aircraft engine components with service temperatures below 700°C. The alloy has a combination of exceptional corrosion resistance at temperatures upto 1000°C with outstanding weldability and resistance to post-weld cracking. Due to its excellent creep-resistant properties, the alloy can withstand ruptures due to creep upto 700°C.

The following stainless-steel grades are available for manufacturing products at PRIMAEAM –

IN625

IN625 is a precipitation-hardenable nickel-chromium alloy containing also significant amounts of iron, niobium, and molybdenum along with lesser amounts of aluminum and titanium. It is widely used in aircraft engine components with service temperatures upto 650°C.

IN718

IN718 is a Precipitation-Hardenable Nickel-Chromium alloy with a density of about 8.2 g/cm3. It is widely used in components for gas turbines, rocket parts, and general high temperature environments. The alloy has exceptional, tensile, fatigue, creep and rupture strength at temperatures upto 700°C.

Pure copper has one of the highest electrical and thermal conductivities of all metals. It shows good corrosion resistance in several environments as well as antibacterial behaviour. The electrical and thermal conductivity in particular make pure copper an excellent choice for applications such as heat exchangers and induction coils, but also for electrification components which are gaining attention from the industry.

Industries & Applications

HEALTHCARE

We contribute to human welfare by application of biomedical engineering and Additive Manufacturing in the research, design and manufacture of Human implants and prosthetics that alleviate pain, restore health, and extend life.

Implants are printed with trabecular structure for excellent Osseointegration (Bone growth).

Electron beam melting process which is adopted by us is helpful for elimination of heat treatment.

Pre-Operative Surgical Planning

Anatomical models printed with us help surgeons to practice and prepare before performing complicated surgeries. This has been the game changer in saving many lives, since the advent of additive manufacturing.

Orthopedic Implants

Our EBM Machine is capable of building full stack of Orthopedic implants such as Acetubular Hip Cup, Knee and Spinal cages. This allows for economy of scale & fastest production in AM.

Custom Designed Implants & Prosthetics

MRI and CT scan data are used to design implants (EBM) and prosthetics (MJF) specific to individual patient’s anatomy.

Surgical Guides & Tools

3D printed Orthopedic tools, abutments & surgical guides can precisely locate drills used during surgery. Physicians can now create guides that suits a patient’s unique anatomy by AM.

Medical Devices

AM enables us to quickly produce prototypes from new design concept. This helps to reduce the time and cost of proto development.

AEROSPACE

We strive to be the partner of choice for world leading aircraft manufacturers by providing lighter parts, durable and safety critical components.

Part Consolidation (Reduction of number of Parts).

Additive manufacturing allows printing of fully assembled parts, with ease. Leading to shortening of the assembly process, reduction in the number of components and reduced weight.

Light Weight Parts (Topology Optimization).

Additive manufacturing facilitates innovation in terms of design. Transforming plain solid parts to interesting structures such as lattices.

End Use Parts.

- Engine components (Turbine Blades, Nozzle).

- Heat exchangers.

- Cabin Interiors (Cabin storage bin, Door latch, Custom cosmetic & Decorative Components, Display shroud, Arm rest cap, Seat end caps, Wall Panels, Tray table).

- Environmental control system ducting.

- Composite layup tools.

- Maintenance, Repair and Overhauling Parts (MRO).

AUTOMOTIVE

We provide our customer with world class aerodynamic, aesthetic, durable, ergonomic products and in doing so exceed their expectation in quality, delivery, and cost.

Conceptualization

Accurate models allow the design intention to be clearly communicated and showcase the overall form of a concept.

Design & Functional Validation

AM allows full testing and validation of the prototype performance before vehicle launch and thus aids in the reduction of development cycle time.

Customisation & Spare Parts

Parts can be tailor made to meet customer needs.

AM has an immense potential for spare parts availability in case of redundant models where parts availability is an issue.

End Use Parts.

- Engine Parts (Housing, Inlet manifold & other metal components)

- Transmission parts

- Interiors (Dashboard, Handles, Gear box knob, AC vent)

- Custom cosmetic & Decorative Components

GENERAL ENGINEERING

We are inclined to meet consumers expectations for the existing products to be made faster and better at low cost.

Economic production of Complex Parts

Additive manufacturing allows for innovative shapes and complex geometry. This reduces the number of parts thereby reducing the assembly time, improving the performance, and emission reduction.

Fast Prototyping of Parts

With AM’s capacity for rapid prototyping, companies are able to develop and validate their designs faster, thereby accelerating the design process and allowing enterprises to better react to emerging market opportunities.

Spare Parts availability

AM reduces warehouse stocks through on-demand printing. 3D printing is the perfect antidote to the ongoing challenge of addressing the requirements of legacy installations.

End Use Parts

- Printing Intricate Parts: Jigs, Fixtures, Molds, Patterns.

- Tooling: Conformal cooling molds and Inserts.

- Rigid Housing.

- Retrofitting: Spare Parts.

- Heat Exchangers.

- Connectors.

- Enclosure.

PRIMAEAM INNOVATION AND INCUBATION CENTER (PIICH)

We contribute to human welfare by application of biomedical engineering and Additive Manufacturing in the research, design and manufacture of Human implants and prosthetics that alleviate pain, restore health, and extend life.

The uniqueness of the PRIMAEAM Incubation centre is that, not only does the incubatee get access to the software but can also give a physical shape to the design through our inhouse world class additive manufacturing facility.

Get in touch

Administrative Location

Ambattur Industrial Estate, Chennai, Tamil Nadu – 600058

Customer Experience Center

Tamil Nadu – 600058

Contact Us

- info@primaeam.com

- franklin@primaeam.com

- +91 98948 42487

Working Hours

- MON to SAT - 09.00 to 18:00